1. Prescription

HD Optical Distribution Frame is a high-capacity fiber patch panel that provides fiber optic cable fixing, stripping, splicing, terminal and scheduling functions.

2. Features

(1)Rack frame should be steel welded closed structure.

(2) Rack with full frontal operation.

(3)At the bottom of the two sides of the rack there is a large enough fiber to take off the fiber hole to meet the need for patch cords.

(4) Fully modular design, using 24-core fusion wiring module integration.

(5)Can be installed splitter module.

(6) Frame body has a perfect protective grounding system. And to ensure that the cable core and armor layer to strengthen ef fective grounding.

(7)Equipment jumper out of their own independent, non-interfering.

(8)There is enough fiber cabling space to ensure the radius of curvature of the fiber.

(9) Unique jumper management program, so that the wiring clear and orderly, neat and beautiful, easy to maintain.

3. Technical parameters

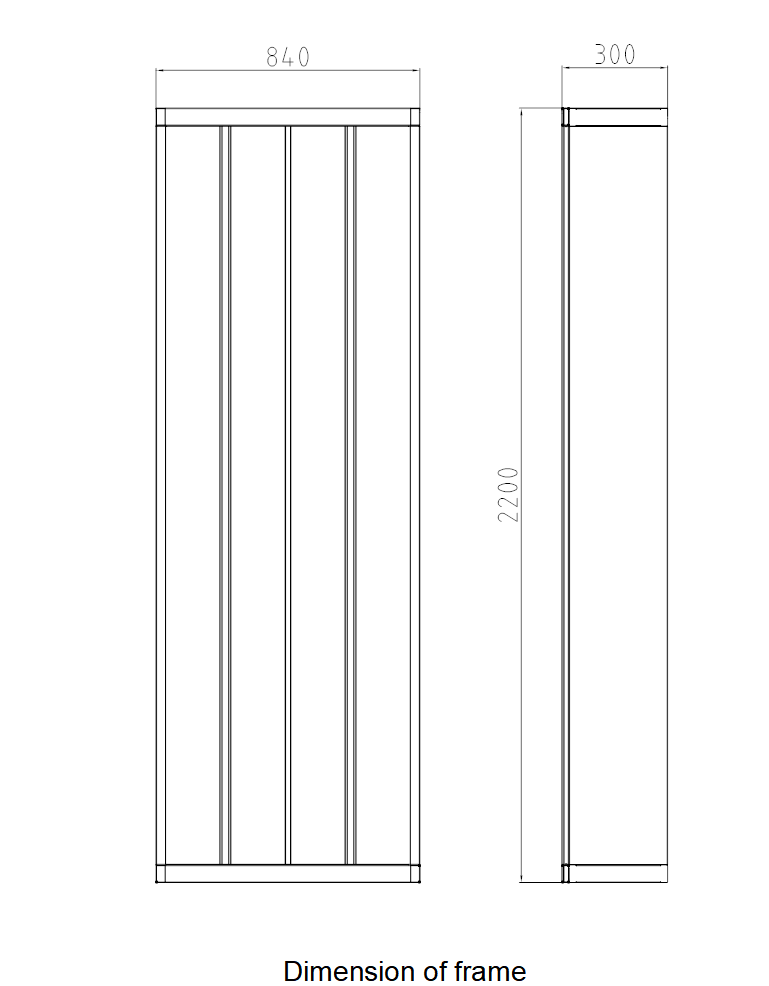

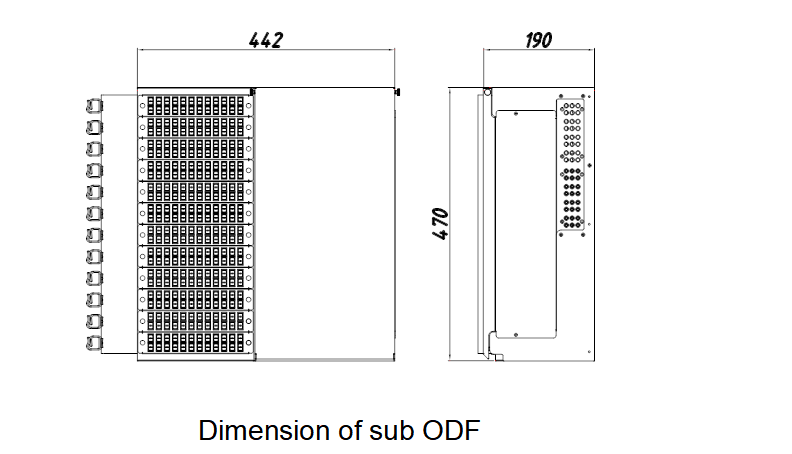

Dimension(mm) H ×W×D | Sub ODF | Maximum Splicing capacity | Installation size (mm) |

2200×840×300 | 4 Pcs | 2304 | 773*213 |

4. Product installation

4.1 .Install tools

Fiber patch panels in the installation of fixed, it will use the impact drill, hammer, socket wrenches, wrenches, screwdrivers (one word and cross) and other installation tools.

4.2 .Rack installation and fixed

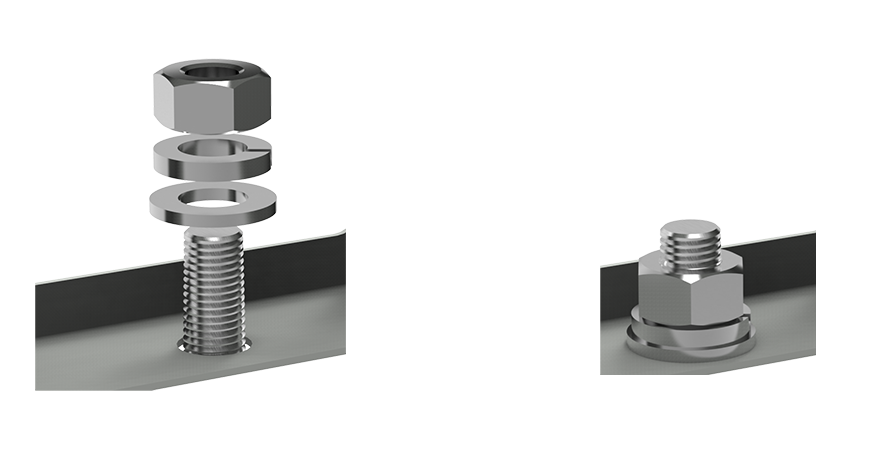

1) According to the installation size specifications in the selected location with the impact drill on the ground for drilling.

2) Push the distribution frame to the appropriate position and the bottom of the fiber distribution frame through the trunking, and

then use four M12 * 140 expansion bolts to fix the frame on the ground (the expansion bolt is hammer in front of the front The

holes in the expansion, the expansion bolt nut can be wrench or socket wrench tighten), the top left of the rack has four pairs of

rack mounting holes, so that the rack body and the top of the cable rack connection, in order to ensure solid rack installation is

solid and reliable.

5. Optical cable installation

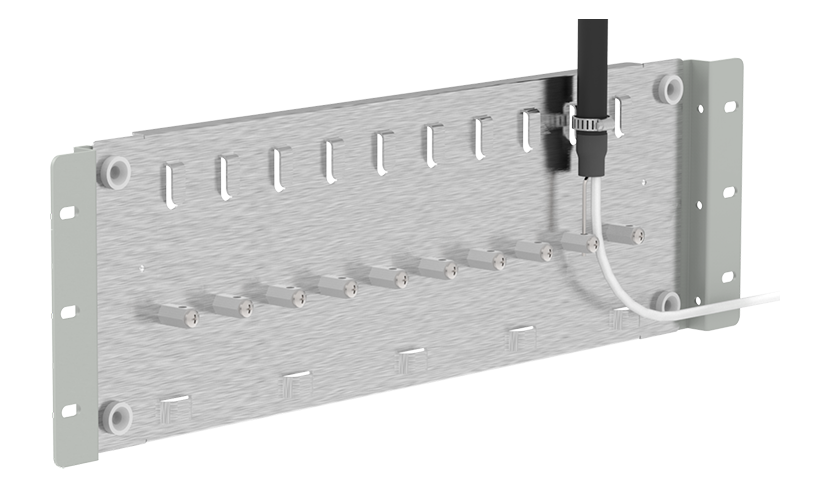

1) The external optical cable from the top or bottom of the frame into the optical fiber distribution frame cable fixing unit (rack and fiber optic cable fixed unit entrance to be protected lines, to protect the external optical cable from damage), and then pulled out about 3~5 meters of optical cable long.

2) Clean fiber optic cable, the cable appearance of dust, debris, oil erase;

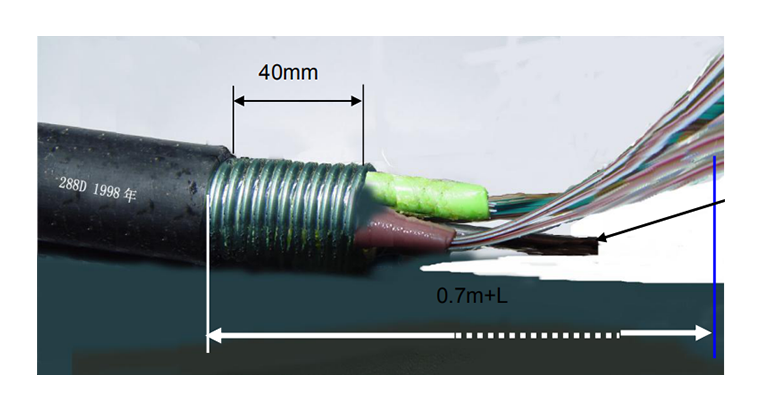

3) Stripping cable, cable stripping pliers to open the outer skin of the cable, optical fiber stripping length L (fiber to the splice tray distance) +700 mm (splint tray disc length) (for reference only), armor layer pre Stay 40mm, the center to strengthen the core set aside 150mm;

4) The optical fiber reinforced core through the optical cable stripping protection device on the optical cable to strengthen the core hole after the card into the core reinforcement, tighten the screw will strengthen the core pressure jail;

5) Wipe the surface of bare fiber oil and dust, and then put a bare band protection sleeve ribbon;

6) The bare sleeve of the protective sleeve gently snapped into the cable stripping and stripping protective device cable clamp slot, and then cover the stripping protection device cover;

7) Fix the optical cable stripping protection device on the optical cable fixing plate with the screw and tie the optical cable to the optical cable fixing plate with the laryngeal buckle.

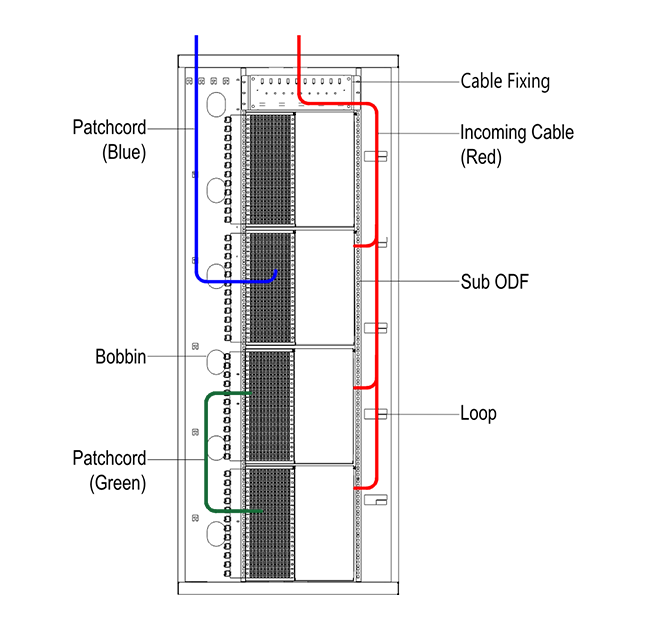

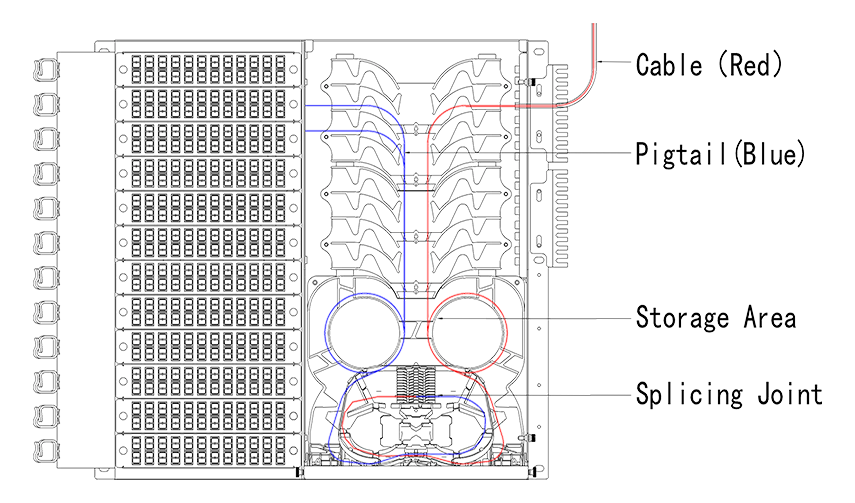

6. Take the fiber route

(Routing in the frame)

(Routing in the sub ODF)

Note:Never look at the adapter in order to avoid hurting the eyes!